The visual inspection and protection of surgical instrumentation is a critical step in the sterilization process, encompassing various stages such as decontamination, assembly, sterilization, and point of use. At the point of use, there are multiple visual inspections when the end-user inspects during the surgical case to when they prepare instruments for transportation. The inspection touch points continue during decontamination and in preparation and packaging. Some of these stages even allow for detailed visualization through lighted magnification. The number of visual checks amounts to at least six, involving different technicians at each stage, beginning at the point of use in a surgical case and ending with that same touch point.

At the preparation and packaging stage, there are many inspection touch points and visibility opportunities, as well as opportunities to inspect instrumentation for functionality. These inspection tasks involve ensuring that the teeth in an Adson forceps are intact and meet properly. Often these forceps can get damaged during the processing stages because the tips and teeth are so small and fragile. Suppose heavy instruments are placed on top of them, or they get caught in the mesh pan. Suppose they are placed improperly in a mechanical washer during the cleaning process. In this case, the impingement activity and the force of water can further damage the tips or teeth, not to mention the exposure to chemicals, detergents, and even the quality of possibly poor water used during decontamination or steam processes.

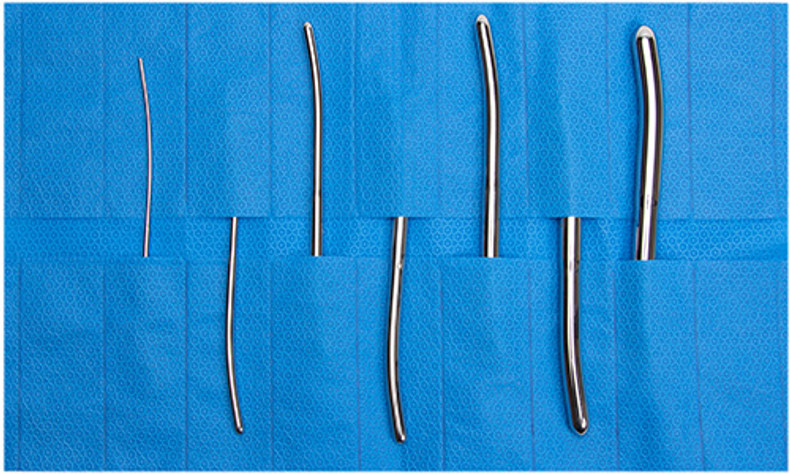

Protection solutions are available to safeguard the delicate tips of forceps or sharp components like double-skin hook retractors. These protective measures help prevent any inadvertent damage and maintain the integrity of the instruments throughout the remainder of the processing tasks. We should consider these protective measures because the ultimate goal in sterile processing is to deliver clean, disinfected, fully functional, and sterile items to customers.

To protect delicate instrument tips and sharp components like double skin hook retractors, protective items are available, such as the Duraholder® Instrument Protection System . This system offers a proven method of safeguarding instruments, reducing the need for repair or replacement. Additionally, it helps organize instrument sets, saving valuable operating room time and complying with AAMI guidelines, as it is made from breathable, non-woven material validated to meet AAMI standards.

Bioseal, collaborating with a leading university hospital, has developed this tool to prevent costly instrument damage, streamline set-up time, and ensure compliance with AAMI guidelines (ST-79). With various grades of Halyard Health* wrap fabric and over 100 styles available, this unique pouch organizes and protects surgical instruments during the sterilization cycle and is compatible with standard steam or EtO cycles.

In Conclusion

In conclusion, the inspection and protection of surgical instruments are essential processes that contribute to the overall safety and functionality of healthcare facilities. The visual inspections conducted at various stages, from decontamination to preparation and packaging, allow for thorough assessments and identification of potential damage or functionality issues.

It is crucial to ensure the integrity of delicate instruments, such as forceps, as they can be susceptible to damage during the processing stages. Protective solutions, like the Duraholder® Instrument Protection System, offer effective safeguards, reducing the need for repairs or replacements and promoting instrument organization. By implementing these measures, healthcare providers can strive to deliver clean, disinfected, fully functional, and sterile instruments to customers, aligning with the goal of sterile processing.

With its versatility and compatibility with sterilization cycles, the Duraholder® Instrument Protection System has gained popularity among customers, making it a trusted choice in the field of surgical instrument protection. Explore the popular configurations of Duraholder® products and discover why they have become a customer favorite.