It is the intent of all Operating Room teams to serve their patients and each other well. After some time working together, they become so in sync that their experience as a team produces laser-focus and delivers efficient and effective care. The team’s oversights or indiscretions do not cause challenges in the Operating Room but outside circumstances that can be avoided and solved.

Well equipped to serve Operating Room needs, Bioseal representatives have a history of forging relationships with Operating Room (OR) and Sterile Processing (SP) staff and decision-makers. Their products and service-oriented performance aids the daily work lives of both departments and help them serve their customers and patients. This article aims to provide insight into those challenges and the solutions Bioseal can provide.

TURNOVER TIME AND INSTRUMENT LOSS

There are many duties the OR staff must perform at the end of a surgical case to prepare for the next. These tasks are expected to be accomplished within a specific time limit; thus, the challenge begins. Hurried to prepare for the following case, turnover time and instrument loss are common challenges for OR managers and teams.

At the end of a case, the OR team moves hastily to work within the parameters of their time constraints. This countdown requires that the team is thorough while feeling rushed - either by the assistants standing at the door who will help turn the room or by the fact that there are no assistants, and this responsibility will also fall on the team. The surgical technologist removes patient disposable drapes and separates reusable towels. Towel clips holding the drapes in place are removed and should be returned at this time to SP to be reprocessed.

The challenge arises when the towel clips and reusable linen are accidentally thrown in the trash with the disposable drapes. The repercussions of this mistake are many, including increased instrument and linen cost, increased surgical minute cost due to delayed turnover times, and devices unavailable for future surgical cases. Not to mention, upon discovering the towel clips disposal, the OR team must now search for the instruments, ultimately causing a delay in case turnover time.

An easy action to help reduce OR turnover times and reduce instrument costs and loss is to implement Bioseal’s disposable towels and towel clips. Both give ease to the team when draping and undraping the patient at the end of the case, decreasing loss and costs and increasing turn times.

The Return of Investment (ROI) for these handy Bioseal Single-Use Device (SUD) towels and towel clips creates a cost reduction for SP technician labor, mechanical equipment use, and surgical minutes. This simple solution also increases staff satisfaction by eliminating the OR team's possibility of digging through the trash and saving the SP Technicians time when reprocessing, re-ordering, searching for towel clips, and preparing linen for sterilization. By managing less instrumentation and Key Performance Indicators (KPI) for turnover times, minutes are added, and stress is reduced for OR and SP teams.

LACK OF INSTRUMENTS

A common challenge working in the OR is the absence or shortage of instruments needed to perform the case. The OR provides an instrument count sheet with the necessary equipment specific to each surgical service. These cases require very different items, and the teams work very hard to devise the count sheets and order the essential instruments to serve the surgeon’s needs. However, in some cases, issues still arise.

When instruments are absent, the SP team will mark the instrument missing on the count sheet to make the OR aware before the case begins. Preparing the room, the surgical technologist and the circulator will attempt to retrieve the missing item by searching the surgical core and other storage areas and calling SP to search in their department.

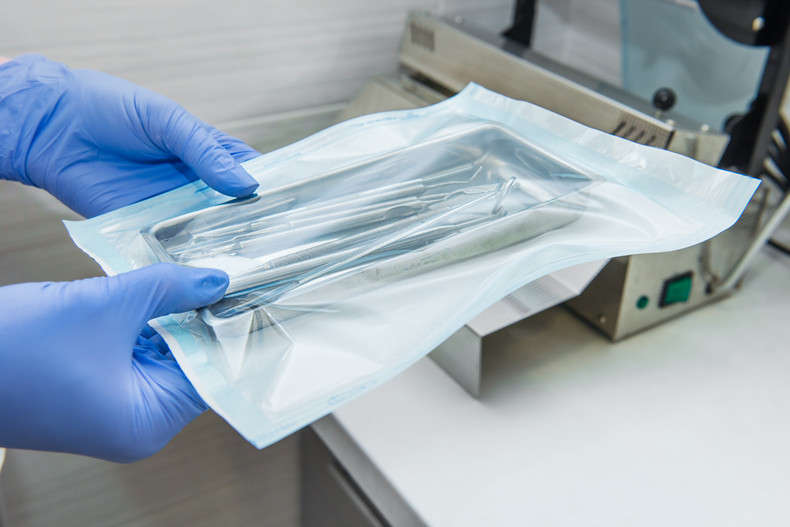

The repercussions for lack of instrumentation are many. One missing instrument can delay cases, create high anxiety in both teams, and eventually create mistrust between OR and SP departments. If specific extra instruments (hemostats, perforated towel clamps, etc..) cannot be retrieved, the OR teams may be forced to resort to opening whole sterile trays to search for one item. This action, in turn, creates a domino effect for both departments. The instrument tray opened for that one item is usually needed for another surgical procedure scheduled for the same day. Although many items are peel-packed, SP does not have all or enough items needed as extra peel packed and sterilized ready for use, increasing the demand and workload for SP technicians.

Bioseal representatives and department decision-makers can provide products that solve these challengesto assure instrumentation is available. Working with an OR service line coordinator, the representative can retrieve a list of often unavailable instruments. The Single-Use, processed, packaged, and sterilized items by Bioseal can serve as a cost-saving solution. A specific or general instrument cart can be devised to hold these readily available instruments with easy access to the surgical teams. This cart offers an effective, efficient, and easy solution.

IN CLOSING

The common challenges of OR management and teams often have simple solutions. With collaborative efforts between decision-makers and Bioseal representatives, the daily work of SP and OR departments can be made to offer less stress and run more smoothly. By reducing the challenges, the OR and SP departments can increase staff satisfaction rates and produce a more desirable work environment, thus attracting additional desperately-needed staff.